I. Introduction: The Hidden Dangers of Flashing and the Core Pain Points of Users

1.1 What is the flickering effect of LED light strips?

Flicker refers to the phenomenon where the brightness of the LED light strip’s output fluctuates rapidly and periodically over time. Its essence is the alternating light and dark caused by unstable driving current. This fluctuation may be imperceptible to the naked eye or may manifest as a distinct flicker. According to the International Commission on Illumination (CIE) TN 006-2016 standard, when the flicker frequency exceeds 125Hz, the human eye usually cannot perceive it, but latent flicker may still have adverse effects.

1.2 Potential Hazards of Stroboscopic Effects on Life and Health

Low-frequency flicker (100Hz – 120Hz) is likely to cause eye fatigue, headache, dry eyes and other discomforts. Prolonged exposure to it will increase the burden on the eyes. High-frequency flicker (>1kHz), although not visible to the naked eye, can cause stripes and dark bands during high-speed shooting, and may also interfere with the body’s biological rhythm, inhibit the secretion of melatonin, and affect sleep quality. For people with photosensitivity, low-frequency flicker may also increase the risk of epilepsy attacks. For children, long-term exposure may accelerate the progression of myopia.

1.3 Why do most light strips have the problem of flickering?

Many LED light strips on the market have the risk of flickering. The main reasons can be summarized into three points: Firstly, cost control. Inferior products reduce the number of filter capacitors and use cheap driving chips, which are unable to suppress voltage ripples; Secondly, poor compatibility with dimming. Traditional PWM dimming frequencies are too low, especially in low-brightness scenarios, resulting in obvious flickering; Thirdly, design flaws. The power supply and the light strip are not matched properly, and the voltage loss of the long cable is not compensated, leading to insufficient current stability.

II. Core Analysis: The Fundamental Causes of LED Light Strip Flashing

2.1 Instability of Current: The Core Cause of Flashing

The luminous intensity of LED is completely controlled by the driving current. If there is any fluctuation in the current, the light output will inevitably change. Most LED light strips need to convert 220V AC mains power into 12V/24V DC power supply. If the design of the rectification, filtering, and constant current control sections is not perfect, it will lead to current fluctuations, and subsequently cause flickering.

2.2 Two Types of Typical Flashing and Their Causes

Low-frequency flicker (100Hz – 120Hz): This mainly results from insufficient filtering of the voltage ripple after rectification, with residual AC components causing current fluctuations. It is commonly seen in cheap power supplies without electrolytic capacitors or with insufficient capacitance. Long-term exposure to such power supplies can easily cause fatigue.

High-frequency flicker (>1kHz): This is more common in PWM dimming scenarios. Even the low-frequency PWM signals (<200Hz) that are imperceptible to the naked eye can reveal problems during shooting. Some products may also generate resonance due to harmonic interference, exacerbating the flicker phenomenon.

2.3 Supplementary Influencing Factors

Apart from the core driving issues, cable length, compatibility of the dimming system, and electromagnetic interference (EMC) can also cause flicker. For instance, if 12V light strips exceed 5 meters without voltage compensation, the constant current drive will become unstable due to voltage loss; non-intelligent controllers lack high-frequency dimming functions, which may cause conflicts with the light strips.

III. Technological Breakthrough: Our Core Solution for Non-Flickering Drive

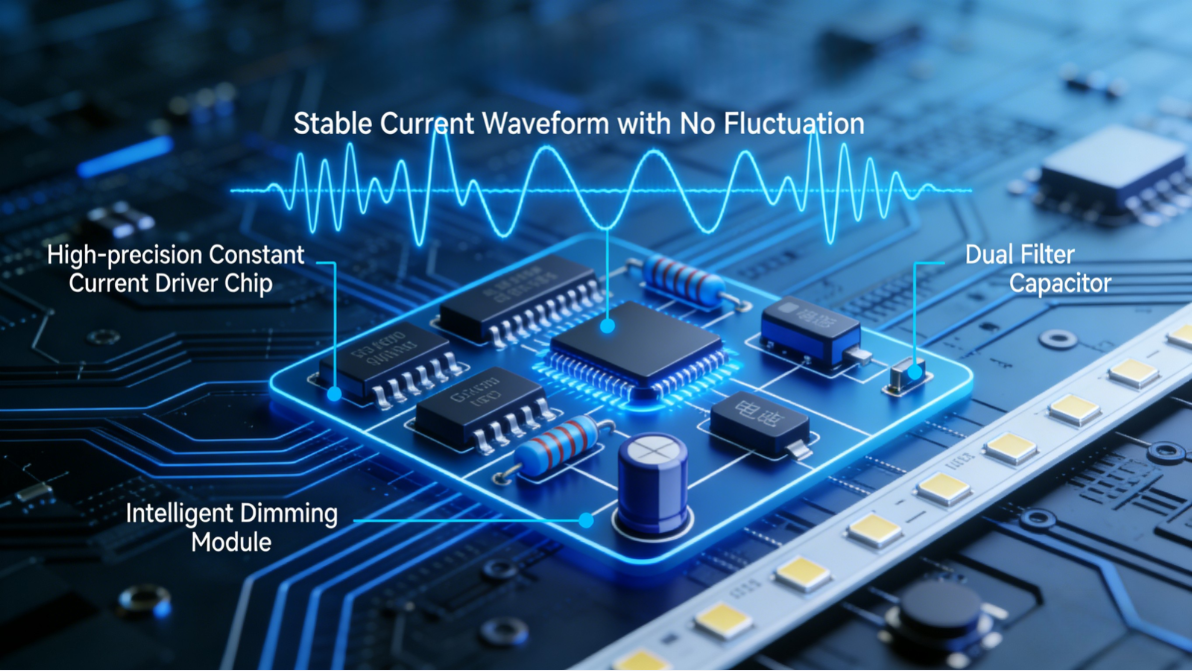

3.1 Core Principle: The essence of no flicker is “steady current + clean waveform”

True flicker-free operation does not merely increase the flashing frequency. Instead, it achieves this through hardware optimization and algorithm control, ensuring a stable output of the driving current, thereby maintaining a smooth current waveform without significant fluctuations. At the same time, it takes into account the light dimming performance, energy efficiency, and electromagnetic compatibility standards. This requires a collaborative breakthrough in multiple technical aspects.

3.2 Hardware Optimization: Suppressing Flashing at the Source

3.2.1 Selection of High-Precision Constant Current Driving Chips

By using high-performance constant current control chips such as TI TPS92662, combined with the Buck/Flyback step-up/down topology structure, a current ripple control of less than 1% is achieved. The ripple suppression ratio exceeds 60dB, ensuring stable and undistorted output current. At the same time, a feedback regulation circuit is integrated to monitor current changes in real time and dynamically compensate for voltage fluctuations and load variations.

3.2.2 Strengthened Filtering and Energy Storage Design

At the power input end, a high-voltage electrolytic capacitor is configured. At the output end, a high-frequency filter capacitor is connected in parallel. The dual filtering network effectively smooths the voltage ripple and avoids the residual of AC components. Regarding the issue of capacitor lifespan, long-life electrolytic capacitors are selected, and the circuit layout is optimized to balance the capacitor capacity and the product volume. This ensures the filtering effect while extending the overall lifespan.

3.2.3 Innovative Light Source Module and Circuit Design

By adopting a hybrid light source structure of “first parallel then series”, the problem of uneven load caused by the error of forward conduction voltage (VF) of LED light beads is solved. This avoids local brightness fluctuations. In the circuit, fast recovery diodes and varistors are connected in series to suppress surge voltages and electromagnetic interference, further improving current stability and meeting EMC standards requirements.

3.3 Light dimming technology upgrade: Balancing flicker-free and dimming experiences

3.3.1 Hybrid Scheme of High-Frequency PWM and Linear Dimming

It adopts a >3kHz high-frequency PWM dimming technology, which is compatible with the DMX512 protocol. Even in low brightness scenarios below 30%, there is no flicker. At the same time, it integrates linear dimming (Analog Dimming). By adjusting the constant current value, the brightness can be changed, avoiding the potential hazards of the switch waveform in traditional PWM dimming, and achieving seamless flicker-free switching across the entire brightness range.

3.3.2 Optimization of Smart Dimming Compatibility

It is compatible with digital dimming protocols such as DALI and 0-10V. It has an internal intelligent recognition algorithm that can automatically adjust the dimming parameters according to different controllers to avoid compatibility conflicts. It separates the RGBW independent channels to reduce PWM signal cross-interference and eliminate the harmonic resonance problem when multiple colors of light are superimposed.

3.4 System-level Protection: Comprehensive Stability Assurance in All Scenarios

3.4.1 Voltage Compensation and Long-Line Power Supply Optimization

For long cable application scenarios, a standardized power supply solution is formulated: for 12V light strips, a power injection point is set every 5 meters; for 24V light strips, supplementary power supply is provided every 10 meters to compensate for voltage loss and ensure uniform current throughout the entire light strip. The control module is equipped with adjustable resistors and capacitors, which can dynamically optimize the power factor according to the load conditions and achieve a stable output with PF > 0.7.

3.4.2 Electromagnetic Compatibility (EMC) Design

By optimizing the circuit layout and configuring balanced common-mode/differential-mode filters, the filtering effect is enhanced while avoiding the introduction of additional ripples due to electromagnetic interference. This achieves the dual goals of eliminating flicker and meeting EMC standards, addressing the technical challenge of “imbalance between filtering and dynamic response” in the industry.

IV. Detection and Verification: Unwavering Proof of Non-Flashy Quality

4.1 Professional Testing Standards and Indicators

Comply strictly with the IEEE Std 1789-2015 standard to ensure that the flicker percentage is less than 5% and the flicker index is less than 0.05, which is far superior to the industry safety threshold. Each batch of products has passed the TÜV non-flicker certification and the IEC/TR 61547-1 electromagnetic compatibility certification, controlling the quality from the source.

4.2 Triple Inspection Process

R&D stage: Use an oscilloscope to test the driving current waveform, identify hidden issues such as 100Hz ripple, and ensure the current waveform is stable; Production stage: Use a strobe light to detect the percentage of strobing and the flicker index, and reject any non-conforming products directly; Factory stage: Sample for smartphone shooting tests to ensure there are no shooting stripes, dark bands, etc.

4.3 Users can verify the method independently

Mobile phone camera method: Turn on the slow video mode of the mobile phone and aim at the light strip. If there are no obvious black and white stripes, it proves that there is no obvious flicker. Long-term experience method: Use continuously for more than 3 hours without eye fatigue or headache symptoms, which meets the requirements of healthy lighting.

V. Product Advantages: The Value of Flash-Free Technology

5.1 Health Protection: Suitable for All Populations

Without flickering light, it avoids eye fatigue and headaches, etc., and is suitable for scenarios such as children’s study and office lighting, as well as for the elderly’s living. At the same time, it eliminates the risk of triggering photosensitive epilepsy, providing a safe lighting environment for sensitive groups.

5.2 Professional Adaptation: Meeting shooting and special scenario requirements

There is no high-frequency hidden flicker. In scenarios such as photography, live streaming, and exhibition lighting, it can prevent the lens from capturing stripes or dark bands, ensuring stable picture quality; the full brightness range has no flicker, and it is suitable for various needs such as ambient dimming and night lighting.

5.3 Long-term Stability: Extending Product Lifespan

Steady current reduces the power consumption of LED lamp beads. Combined with long-life driver chips and capacitors, the product’s service life is increased by more than 30% compared to ordinary light strips. Voltage compensation and anti-interference design enable it to be compatible with 5-20-meter-long cable installations, meeting the needs of large-space decoration.

The absence of flicker in LED light strips is not merely a matter of hardware assembly; it is the result of a comprehensive technological achievement involving power topology, filtering networks, dimming control, and electromagnetic compatibility. We always refuse to compromise on cost and provide users with “unnoticeable to the naked eye, meeting standards for detection, and fully adaptable to various scenarios” LED light strips without flicker, ensuring that every ray of light is both aesthetically pleasing and healthy.

If you are facing flicker issues during home decoration or commercial lighting, please feel free to consult our technical team to obtain customized flicker-free lighting solutions.

Facebook:https://www.facebook.com/profile.php?id=100089993887545

Instagram:https://www.instagram.com/mx.lighting.factory/

YouTube:https://www.youtube.com/channel/UCMGxjM8gU0IOchPdYJ9Qt_w/featured

LinkedIn:https://www.linkedin.com/company/mingxue/

Post time: Jan-27-2026

Chinese

Chinese