Since the end of 2025, the LED industry has witnessed a new round of cost escalation. The copper price has risen by over 36% this year, directly driving a significant increase in the production cost of the core component of LED light strips – the circuit board (PCB). Under the pressure of costs, some unscrupulous manufacturers, in an attempt to seize the market and cut costs, have begun to engage in “deceptive practices” on the circuit boards of LED light strips. They resort to “stealing copper” and “substituting inferior products for good ones” to make huge profits, causing serious quality risks and subsequent losses for the purchasers. This article aims to help you understand the essence of the “stealing copper” trap, master practical methods to avoid it, and ensure that you purchase genuine LED light strips.

I.Industry Background: Why Did the Surge in Copper Prices Give Rise to the “Copper Theft Trap”?

1.1 The chain reaction of the sharp increase in copper prices: The cost of LED light strips is under pressure

Copper is the core raw material for the circuit boards of LED light strips. The thickness of the copper foil directly determines the conductivity, heat dissipation performance and service life of the circuit board. Since 2025, due to factors such as fluctuations in global supply chains and the rising demand for base metals, the price of copper has continued to soar, increasing by more than 36%, resulting in a 15%-25% increase in the cost of PCB boards. For the LED light strip industry, the cost of circuit boards accounts for 20%-30% of the total cost, and the rise in copper prices has directly squeezed the profit margins of enterprises.

1.2 The essence of the copper theft scheme: sacrificing quality for lower prices

In the face of cost pressure, regular enterprises usually optimize production processes, improve efficiency to absorb costs, or reasonably adjust product prices to ensure quality. However, some unscrupulous manufacturers choose to “take shortcuts”, manipulating the copper foil on the circuit board – by reducing the thickness of the copper foil, replacing pure copper with copper-clad aluminum or copper-clad iron, and narrowing the width of the copper wires, etc. to cut corners. The finished products are sold at prices far lower than the normal market prices, trapping the purchasers in the “temptation of low prices”.

1.3 Warning! The hidden dangers of stealing copper wiring strips are far greater than the cost savings.

The purchase of stolen copper lamp strips may seem to have saved procurement costs in the short term, but it actually conceals huge hidden dangers: poor conductivity leads to uneven brightness and flickering of the lamp strips; poor heat dissipation accelerates the aging of the lamp beads, reducing the service life to 1/3 – 1/2 of the normal product; in overloaded or high-temperature environments, it is prone to copper wire burning, short circuits, and even fire risks. For engineering projects, the costs of subsequent rework and replacement are much higher than the initial savings.

II. In-depth Analysis: The 3 Major Copper Theft Traps in LED Light Strip Circuit Boards

2.1 Trap 1: Reducing the thickness of copper foil – The most common method of “stealing copper”

2.1.1 Undercutting Principle: Reducing the Standard Thickness of Copper Foil

The standard thickness of copper foil for regular LED light strip circuit boards is 1 oz (approximately 35 μm). For high-quality products, even 2 oz (approximately 70 μm) is used to ensure stable operation under high current. Poor manufacturers, however, reduce the copper foil thickness to below 0.5 oz (approximately 18 μm), directly reducing costs by decreasing the amount of copper used.

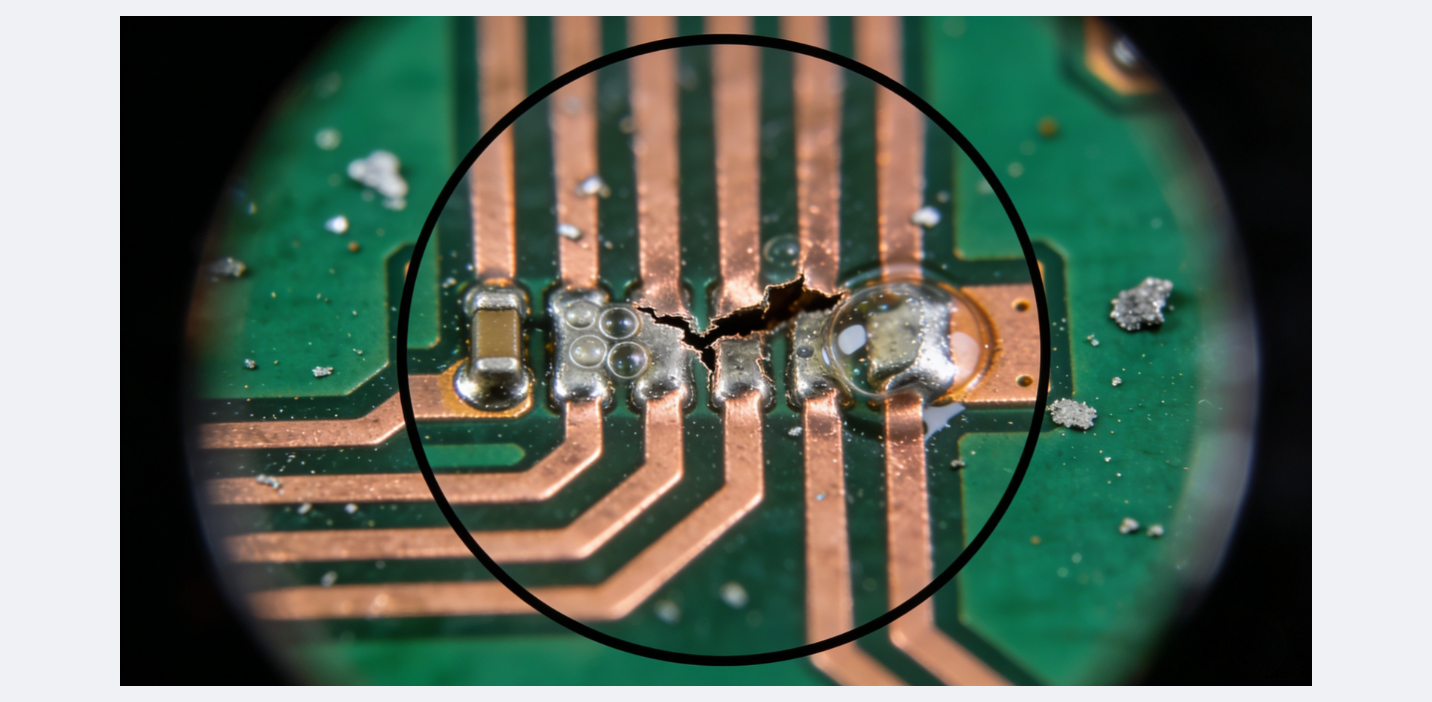

2.1.2 Identification Challenges: The naked eye cannot directly distinguish

The thickness difference of copper foil is only at the micrometer level. It is impossible to distinguish it by the naked eye on the surface of the circuit board. Only by using professional instruments for measurement can it be identified. This provides an opportunity for unscrupulous manufacturers to pass off inferior products as good ones.

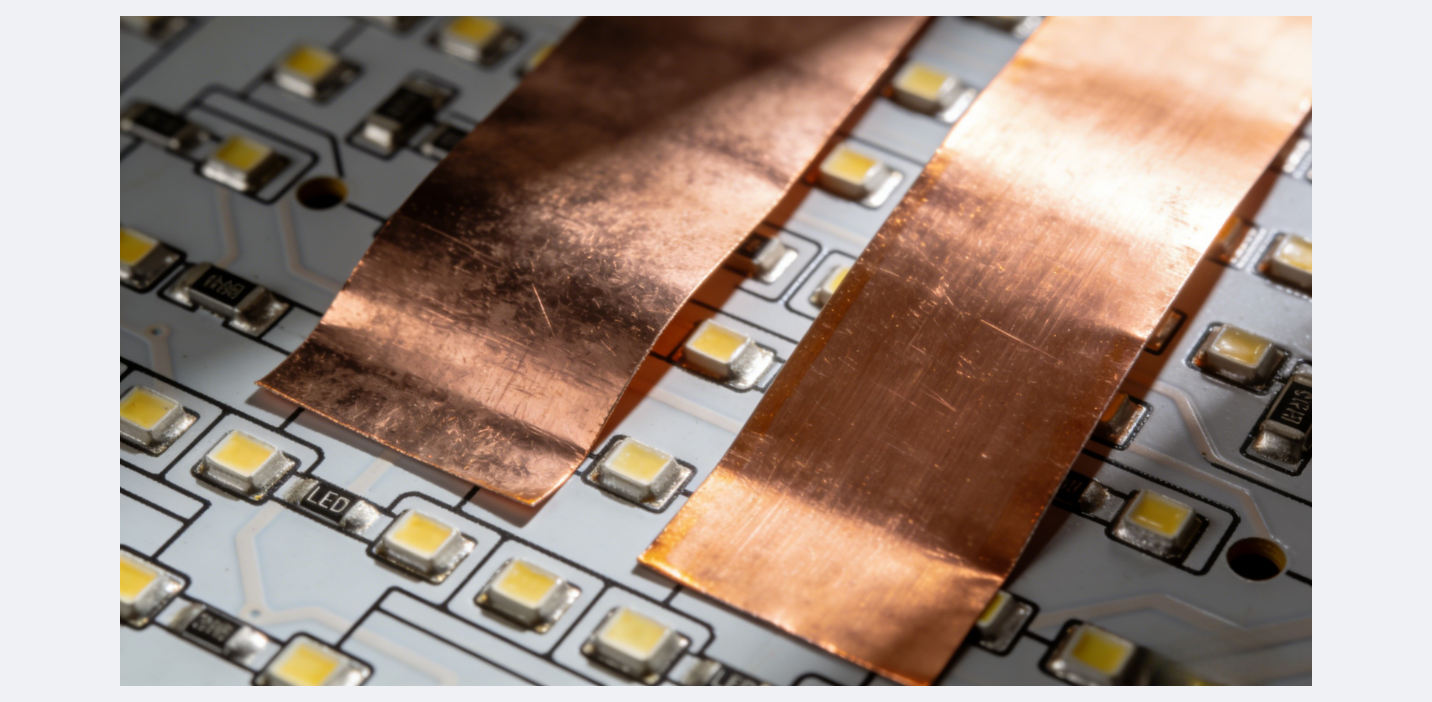

2.2 Trap 2: Material Substitution – Using copper-clad aluminum/copper-clad iron to pure copper

2.2.1 The principle of cutting corners: Using low-cost metals instead of pure copper

Pure copper has excellent electrical conductivity and heat dissipation properties, but its cost is high; while the prices of aluminum and iron are only 1/3 to 1/5 of that of copper. Unscrupulous manufacturers will coat the surfaces of aluminum wires and iron wires with a thin layer of copper to produce “copper-clad aluminum” and “copper-clad iron” circuit boards, and sell them as pure copper circuit boards. As a result, their electrical conductivity and heat dissipation performance are significantly reduced.

2.2.2 Hidden Risks: Highly Oxidizable, Extremely Short Lifespan

The coating of copper-clad aluminum/copper-clad iron circuit boards is prone to wear and oxidation. After being used for a period of time, problems such as poor contact and increased resistance may occur, and even local non-illumination of the light strips may happen. In a humid environment, the oxidation process is faster, and the lifespan is usually no more than one year.

2.3 Trap 3: Confusing Concepts – Using “Copper Compensation” as a “Justification for Stealing Copper”

2.3.1 Misleading by Misusing Terminology: Using Professional Jargon to Mislead the Purchaser

In PCB manufacturing, “copper theft” is a normal process – small copper dots and copper blocks are added to the blank areas of the circuit board to ensure uniform copper foil distribution and avoid deformation and uneven thickness issues during etching and electroplating. However, some unscrupulous manufacturers have falsely claimed these practices of “reducing copper foil thickness” and “shrinking copper wires” as “copper compensation process”, misleading the unprofessional purchasers.

2.3.2 Key Difference: Normal Process Does Not Affect Core Performance

Normal copper compensation does not alter the thickness and width of the copper foil in the core conductive area of the circuit board, and does not affect the conductivity and heat dissipation performance. However, the act of stealing copper directly reduces the amount of copper used in the core area, which is a clear case of quality degradation.

III. Practical Guide: 5 Steps to Avoid the Trap of Stealing Copper from LED Light Strip Circuit Boards

3.1 Step 1: Reject the “Ultra-Low Price Temptation” – Set the Cost Bottom Line

Under the backdrop of the sharp increase in copper prices, the cost of LED light strips has a clear bottom line. If a manufacturer’s quotation is more than 20% lower than the market average price, there is a high probability that they are stealing copper or passing off inferior products as good ones. When purchasing, one should establish a corresponding understanding of “cost – quality”, not blindly pursue low prices, and prefer to choose brands with reasonable quotations and good reputations.

3.2 Step 2: Specify parameters clearly – The contract specifies the thickness of the copper foil

When purchasing, it is necessary to clearly specify the requirements to the manufacturer and include the circuit board parameters in the contract: copper foil thickness ≥ 1oz (35μm), material is pure copper, copper wire width ≥ 1.0mm (adjusted according to power). At the same time, the manufacturer is required to provide a copper foil thickness test report, referring to national and industry standards such as GB/T and IPC-4562.

3.3 Step 3: Master 4 Simple Identification Methods – Operable at the Scene

3.3.1 Magnetization Test Method: Differentiating Pure Copper from Copper-Coated Iron

Pure copper is non-magnetic, while the iron wires in copper-clad-iron circuit boards will be attracted by magnets. When purchasing, you can bring a small magnet and place it close to the copper wires of the circuit board. If there is an attraction phenomenon, it indicates a copper-clad-iron trap.

3.3.2 Abrasion Test Method: Differentiating Pure Copper from Copper-Aluminum Alloy

Gently scrape the copper wires at the edge of the circuit board with a sharp tool. After scraping pure copper, the exposed part remains copper-colored. If it shows a silver-white or gray-white color, it indicates that it is copper-clad aluminum (silver-white) or copper-clad iron (gray-white). Be sure to scrape gently to avoid damaging the circuit.

3.3.3 High-temperature testing method: Evaluation of copper foil quality

Using a soldering iron (with the temperature set to around 350℃), gently touch the copper wires on the circuit board for 10 to 15 seconds. For high-quality pure copper circuit boards, there will be no obvious deformation or blackening; while for circuit boards with inferior copper or those using substitutes, they will quickly turn black, deform, and even have copper wires falling off.

3.3.4 Weight Comparison Method: Preliminary Estimation of Copper Usage

For circuit boards of the same length and width, the pure copper products are 10% – 20% heavier than those made of stolen copper or copper-clad aluminum/iron. During procurement, samples can be randomly selected for weighing and comparison. If the weight is significantly lighter, be vigilant of the risk of stolen copper.

3.4 Step 4: Request an authoritative test report – Professional endorsement is more reliable

Regular manufacturers can provide line board inspection reports issued by third-party authoritative institutions, which clearly indicate key parameters such as copper foil thickness, material, and peel strength. The inspection methods comply with standard procedures such as X-ray fluorescence spectroscopy (XRF) and mechanical sectioning. If the manufacturer is unable to provide the inspection report, or if the report parameters are unclear, one should definitely avoid it.

3.5 Step 5: Select a reputable brand – After-sales service guarantee is the bottom line

Unreliable manufacturers usually lack a comprehensive after-sales service. When quality issues arise, they tend to shift the blame and engage in procrastination. On the other hand, reputable brands will offer clear warranty commitments (such as a 3-5 year warranty for circuit boards) and support free returns and exchanges for quality issues. When making purchases, it is advisable to choose enterprises that have been deeply involved in the industry for many years, possess clear production qualifications and a good brand reputation.

IV. Brand Assurance: How do we uphold quality and avoid the trap of counterfeiting?

4.1 Raw material control: Adhere to pure copper substrate and clearly define the copper foil standards

Our LED light strip circuit boards are all made with 100% pure copper substrates. The copper foil thickness strictly follows the 1oz (35μm) standard. For engineering-grade products, it can be upgraded to 2oz (70μm) as per requirements, effectively eliminating issues such as copper theft and material substitution from the very beginning. All raw materials are sourced from reputable suppliers, and material certificates and test reports can be provided.

4.2 Production Control: Full-process quality control to ensure parameter compliance

During the production process, we use professional equipment such as eddy current meters and X-ray fluorescence spectrometers to test the copper foil thickness of each batch of circuit boards, ensuring that they meet the parameters stipulated in the contract. At the same time, we strictly distinguish between the “copper compensation process” and the core circuit areas to guarantee the stability of the conductive and heat dissipation performance.

4.3 After-sales Guarantee: Full compensation for quality issues, ensuring peace of mind for the purchasers.

All the circuit boards of our LED light strips are made of pure copper. The copper foil thickness meets the standards. If any issues such as copper theft or material substitution are detected by authoritative institutions during the inspection process, we will fully compensate for the purchase cost and bear the related costs for rework and replacement. At the same time, we offer a 3-5 year warranty service, and our professional after-sales team will respond within 24 hours.

V. Conclusion: During the period of copper price surge, when purchasing LED light strips, one must “focus on quality and avoid traps”

Under the backdrop of the soaring copper prices, “low price” is often the “bait” of the copper theft trap. When purchasing LED light strips, do not only focus on the price, but also pay attention to the copper foil thickness, material and other core parameters of the circuit board. By following the five steps of “refusing low prices, clarifying contracts, on-site identification, requesting reports, and choosing brands”, you can effectively avoid the copper theft trap.

Choosing a reputable brand not only allows you to obtain products made of genuine materials, but also enables you to enjoy complete pre-sale consultation and after-sale protection, avoiding greater losses in the future due to quality issues.

Free consultation: Provide your procurement requirements (for household, commercial or engineering use), and receive suggestions for selecting circuit board parameters;

Sample testing: We offer free delivery of LED light strip samples. We can also assist in contacting third-party institutions to test the thickness and material of the copper foil.

Product View: Click to enter the [High-Quality LED Light Strip Product Zone], where you can learn about the circuit board parameters, production processes, and prices.

Facebook:https://www.facebook.com/profile.php?id=100089993887545

Instagram:https://www.instagram.com/mx.lighting.factory/

YouTube:https://www.youtube.com/channel/UCMGxjM8gU0IOchPdYJ9Qt_w/featured

LinkedIn:https://www.linkedin.com/company/mingxue/

Post time: Jan-15-2026

Chinese

Chinese