In the decision-making process of purchasing LED light strips, the choice between high voltage and low voltage is an unavoidable core issue. Many users are confused: Is the installation of high-voltage light strips simpler? Is the safety of low-voltage light strips really higher? How much is the difference in installation costs between the two? In fact, there is no absolute superiority or inferiority between these two types of light strips. The core differences lie in three dimensions: safety, installation cost, and applicable scenarios. This article, through clear general and minor Outlines, helps you comprehensively clarify the differences between the two from basic understanding to in-depth comparison, and then to scenario-based selection, precisely matching project requirements.

The core definitions of high-voltage and low-voltage LED light strips:

●The core feature of high-voltage LED light strips is that their input voltage is 220V mains power, eliminating the need for additional transformers and allowing them to be directly connected to household or engineering power supply lines. Its structure is mostly packaged with hard PCB boards, and the LED beads are neatly arranged. The common specifications are 12W-24W per meter, with stable brightness output, making it suitable for large-scale and long-distance laying. Our high-voltage light strips feature a surge protection drive design, effectively resisting voltage fluctuations. They also have an IP65 waterproof rating, making them suitable for outdoor basic lighting scenarios.

●The input voltage of low-voltage LED light strips is 12V or 24V DC voltage. They must be used in conjunction with a transformer. Only after converting 220V mains power to low-voltage DC power through the transformer can they operate. Its material is mostly flexible PCB boards, which can be bent and cut, suitable for complex shape installation. Common specifications are 5W-20W per meter, with soft light and outstanding safety. All of our low-voltage light strips adopt constant current drive solutions, featuring slow light attenuation and long lifespan. They also support customized waterproof grades (IP44-IP67), covering various scenarios such as household and commercial use.

Safety – Low-voltage light strips have significant advantages, while high-voltage ones require strict control and protection:

①High-voltage LED light strips: They have relatively high safety risks and strict protection requirements

●- Electric shock risk: Direct contact with 220V high voltage can easily cause electric shock accidents, especially in damp environments (such as bathrooms, outdoor rainy days), the risk doubles.

●- Fire hazard: If the wiring ages, the joints become loose or it is overloaded, short circuits and overheating are likely to occur, which may cause a fire.

●- Protection requirements: Insulation treatment must be done well. Joints should be sealed with dedicated waterproof terminals. For outdoor use, IP65+ waterproof grade should be selected, and the installation personnel must have an electrician’s qualification.

②Low-voltage LED light strips: With a maximum safety factor, they are applicable in a wider range of scenarios

●- No risk of electric shock: Powered by 12V/24V low voltage, it won’t cause electric shock even if touched directly. It is suitable for children’s rooms, baby stores, bathrooms and other places with frequent touching or high humidity.

●- Low fire risk: With low voltage and high current characteristics, the drive power supply will automatically protect itself (cut off power/limit current) when the line is overloaded to prevent overheating.

●- Flexible protection: Basic insulation is sufficient for indoor use. In damp or outdoor scenarios, only the waterproof level of the light strip itself needs to be enhanced. The installation threshold is low and it can be operated without professional electricians.

Installation cost – High voltage saves in the early stage, low voltage offers long-term value:

①The initial procurement cost: High-voltage light strips have more advantages

●High-voltage LED light strips: No additional transformer needs to be purchased. The price per meter is approximately 15 to 30RMB. When purchasing on a large scale, the initial investment is relatively low.

●Low-voltage LED light strips: An additional transformer (12V/24V constant current drive) is required. The unit price of the driver is approximately 50 to 200RMB (classified by power). Plus the light strip itself (20 to 40RMB per meter), the initial procurement cost is 20% to 40% higher than that of high-voltage ones.

②Installation labor cost: High pressure requires professional construction, while low pressure is more worry-free

●High-voltage LED light strips: Professional electricians are required for wiring and connection, with proper insulation and protection. Calculated based on a 100-meter installation, the labor cost is approximately 800 to 1,200RMB.

●Low-voltage LED light strips: The wiring is simple. Just connect the light strips to the driver and then connect to the mains power. Even beginners can operate it. The labor cost for laying 100 meters is about 300 to 500RMB. You can even DIY it yourself to save labor costs.

③Later maintenance cost: Low voltage has a long service life, making maintenance more cost-effective:

●High-voltage LED light strips: Due to the high voltage, the circuits and LED beads are prone to aging, with a lifespan of approximately 3 to 5 years. The cost of replacing the circuits and repairing faults in the later stage is relatively high, and it is also difficult to troubleshoot.

●Low-voltage LED light strips: They adopt constant current drive, with slow light attenuation and a lifespan of approximately 5 to 8 years (our products come with a 3-5 year warranty). In the later stage, only regular driver checks are required, resulting in low maintenance costs and simple fault detection (mostly driver issues, just replace them directly).

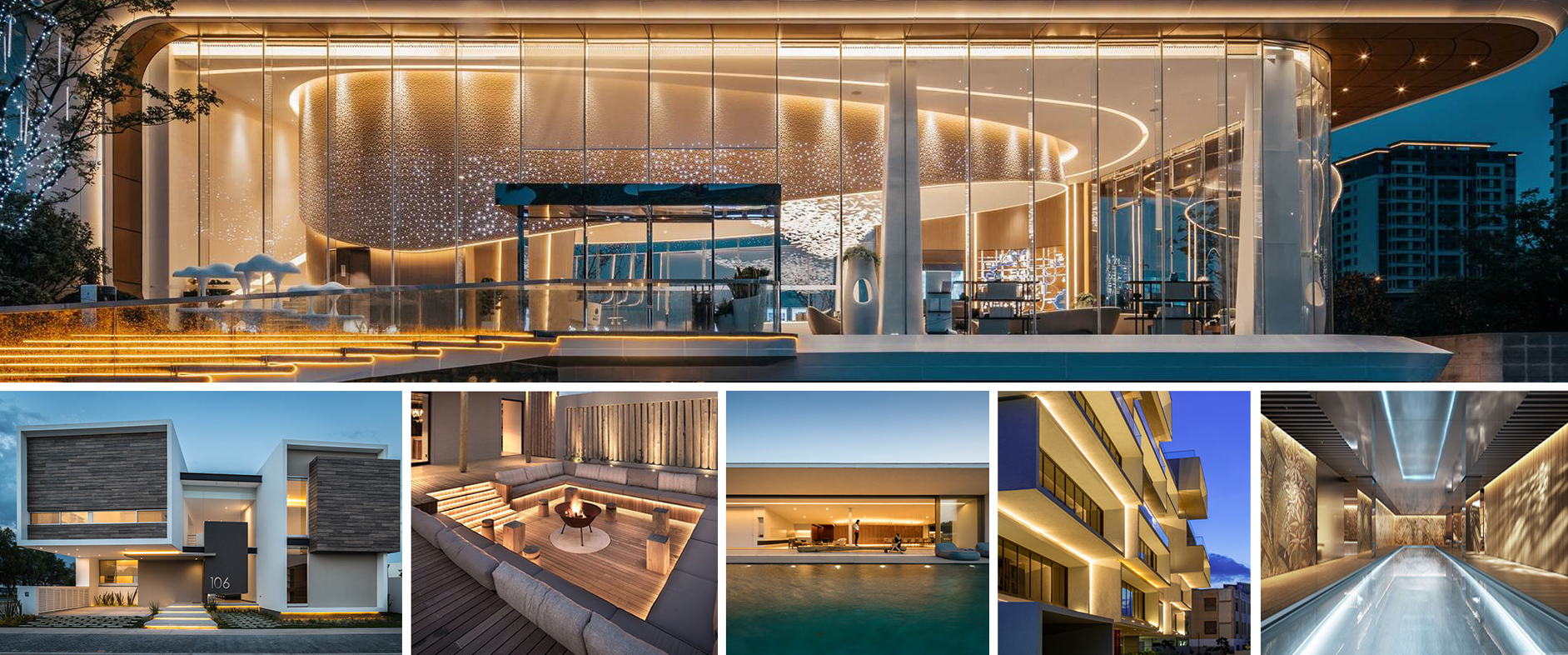

Prioritize scenarios where high-voltage LED light strips are preferred:

①Large-scale outdoor engineering lighting (touchless, dry environment)

②Temporary lighting or low-cost budget projects

Prioritize scenarios where low-voltage LED light strips are preferred:

①Home decoration scenarios (Safety first

②Business scenarios (emphasizing experience and security

③Damp/wading surrounding scenes

Four key points to Avoid pitfalls when making a purchase:

①When choosing low-quality high-voltage light strips for the sake of cheapness, make sure to recognize the “3C certification” and avoid products without insulation protection.

②For low-voltage light strips, the quality of the driver should be ignored. Poor-quality drivers can easily cause the light strips to flicker and have rapid light attenuation. It is recommended to choose brand constant current drivers first.

③Confuse the waterproof grade. For outdoor scenarios, it is necessary to clearly define the waterproof grade of the light strip (IP65+) to prevent rain erosion.

④Choose the type blindly without considering the installation environment. Avoid high-voltage light strips in damp or touch scenarios and give priority to low-voltage ones.

Contact us for more information and samples of LED light strips!

Facebook:https://www.facebook.com/MingxueStrip/ https://www.facebook.com/profile.php?id=100089993887545

Instagram:https://www.instagram.com/mx.lighting.factory/

YouTube:https://www.youtube.com/channel/UCMGxjM8gU0IOchPdYJ9Qt_w/featured

LinkedIn:https://www.linkedin.com/company/mingxue/

Post time: Dec-25-2025

Chinese

Chinese